In modern wastewater treatment plants striving for efficiency, stability, and low operational costs, the selection and dosing method of flocculants are critical. While traditional powdered polyacrylamide (PAM) is effective, its long dissolution time, tendency to form clumps, complex feeding equipment requirements, and dust-related hazards often pose operational challenges. Today, a revolutionary product—Easy-Dose Polyacrylamide Emulsion—is gaining prominence in the water treatment sector due to its exceptional convenience and high performance.

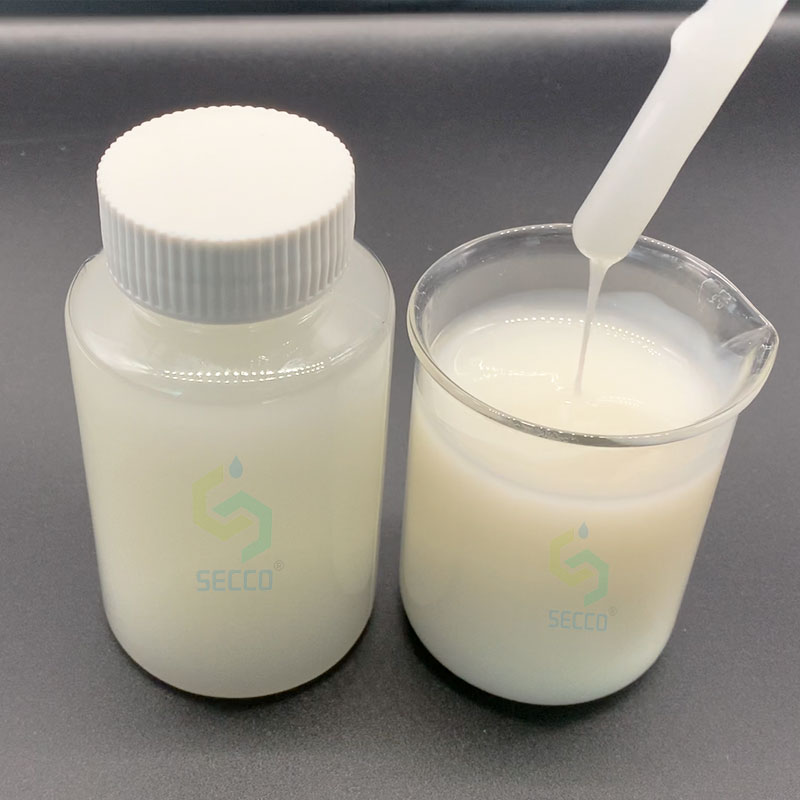

Polyacrylamide emulsion is a liquid formulation where active PAM components are stably dispersed in an oil phase. Compared to powdered products, it offers these core characteristics:

Form & Solubility: A milky-white liquid with good fluidity. Its “inverse emulsion” property allows it to quickly break, disperse, and dissolve in water, typically within 10-30 minutes, significantly faster than the 40-90 minutes required for powdered products.

High Active Content: Contains a high concentration of active ingredients (usually ≥30%), delivering outstanding flocculation efficiency per unit dose.

Stability: Offers stable performance with a long shelf life and resists degradation, avoiding issues like moisture absorption and caking common in powders.

“Easy-Dose” embodies the product’s comprehensive benefits in simplifying processes, enhancing automation, and reducing total cost of ownership:

Extremely Simple Dosing Operation

No Complex Dispersion Needed: Can be directly injected into a dilution tank via a metering pump, eliminating the need for specialized powder dispersion units and lengthy pre-wetting/stirring processes.

High Automation Compatibility: Its liquid form allows seamless integration with existing automated dosing systems (PLC-controlled), enabling precise continuous dosing and instantaneous adjustment based on influent flow or turbidity changes.

Ready-to-Use & Fast Response: Allows for quick start-up and effectiveness during water quality fluctuations or emergencies, improving the system’s resilience to shock loads.

Significantly Reduces Operational & Labor Costs

Labor Savings: Eliminates heavy manual tasks like bag handling, opening, and powder pouring, along with associated health and safety measures.

Energy Savings: Drastically reduces or even eliminates the energy required for high-speed mixing and dissolution.

Reduces Waste: Precise liquid metering prevents product loss from dusting and bag residue, achieving near-100% utilization.

Simpler Maintenance: The dosing system is less prone to blockages in pipes and equipment caused by powder clumping and wall adhesion, lowering maintenance frequency and costs.

Improved Safety & Working Environment

Dust-Free: Creates a clean dosing environment, protects worker respiratory health, and completely eliminates the potential risk of dust explosion.

Safe Storage: Typically supplied in drums, requiring less storage space and relatively simple conditions (avoid light, room temperature).

Easy-dose PAM emulsion is suitable for various solid-liquid separation processes:

Primary Sludge Flocculation: Enhances the settlement of suspended solids in primary clarifiers, improving SS removal rates.

Waste Activated Sludge (WAS) Thickening: Dosed before gravity thickeners or mechanical concentrators to significantly increase sludge solids content and reduce downstream processing volume.

Sludge Conditioning for Dewatering: A key conditioner before belt filter presses, centrifuges, or plate & frame filter presses. It improves filterability, increases cake dryness, and reduces filtrate turbidity.

Chemically Enhanced Phosphorus Removal: Works synergistically with aluminum or iron salt coagulants to form denser flocs, enhancing phosphorus removal and advanced turbidity reduction.

Industrial Wastewater Pretreatment: Effective for flocculation and separation in challenging industrial streams such as oily wastewater, textile dyeing effluent, and mining wastewater.

To maximize the benefits of easy-dose PAM emulsion, consider the following points:

Dilution & Aging: Typically requires dilution with clean water in a dedicated tank to a concentration of 0.1%-0.5%. Although dissolution is rapid, a gentle aging period of approximately 15-30 minutes is recommended to allow for complete polymer chain extension.

Product Selection & Compatibility: Choose the most suitable ionic type (cationic, anionic, or non-ionic) based on wastewater characteristics (pH, ionic strength, sludge type). Conduct systematic jar tests to determine the optimal product type, dosage, and dilution ratio.

Equipment Configuration: The core requirement is a precise mechanical diaphragm or peristaltic dosing pump, coupled with level sensors and flow meters for automated control. The dilution tank should be equipped with a slow-speed mixer.

Storage & Handling: Avoid prolonged exposure to high shear or freezing. Gently roll or stir the container before use to ensure emulsion homogeneity.

Easy-dose Polyacrylamide Emulsion represents more than just a change in product form; it signifies an evolution towards smarter, more user-friendly, and more economical flocculant dosing in wastewater treatment. For modern treatment plants focused on enhancing operational efficiency, lowering overall costs, and achieving refined process management, adopting this emulsion solution is a strategic step forward. When considering upgrades to dosing systems or seeking superior flocculation options, this “easy-dose” tool is undoubtedly a highly efficient choice worthy of thorough evaluation.

By embracing this innovative technology, wastewater treatment plants can redirect focus towards core process optimization rather than routine chemical handling, thereby more reliably achieving the balance between environmental compliance and sustainable operation.