1. Role and Effects of Polyaluminum Chloride (PAC)

Mechanism of Action:

Coagulation: PAC is an inorganic polymer coagulant. Upon dissolution, it hydrolyzes to form positively charged aluminum hydroxide colloids. These colloids neutralize the negative charges on suspended solids, colloids (e.g., oils, fine dust), and some heavy metal ions in the wastewater, causing them to destabilize and form micro-flocs.

Demulsification and Oil Removal: PAC can break the charge stability on the surface of emulsified oil droplets commonly found in steel plant wastewater, facilitating oil-water separation.

Removal of Phosphates and Organics: It reduces phosphate and some dissolved organic content through complexation and precipitation.

Effects in Steel Plant Wastewater:

Rapid Settlement of Suspended Solids: Removes over 80% of scale, iron oxide, and dust from processes like rolling and continuous casting.

Reduces Turbidity and Color: Effectively clarifies wastewater and improves its visual quality.

Good Adaptability: Relatively tolerant to pH variations (optimal range 6-9) and temperature fluctuations, suitable for the variable quality of steel plant effluent.

Secco’s PAC Solutions: We offer a range of PAC products with varying basicity and aluminum content to match specific water quality conditions, ensuring optimal coagulation efficiency.

2. Role and Effects of Polyacrylamide (PAM)

Mechanism of Action:

Flocculation and Bridging: PAM is an organic polymer flocculant. Its long-chain molecules adsorb onto multiple micro-flocs, “bridging” them to form large, dense agglomerates (flocs) that settle rapidly.

Sweep Flocculation: The settling flocs entrap finer particles, enhancing overall purification.

Sludge Dewatering Aid: In subsequent sludge treatment, PAM (especially cationic types) compresses sludge particles, releases bound water, and significantly improves dewatering efficiency.

Effects in Steel Plant Wastewater:

Enhanced Solid-Liquid Separation: When used with PAC, PAM increases floc size and density, accelerating settlement rates multiple times and improving clarifier throughput.

Reduces Sludge Moisture Content: As a dewatering agent, it can lower sludge cake moisture from >95% to 60-80%, reducing disposal costs.

Targeted Selection:

Anionic PAM: Often used in neutral/alkaline wastewater, combined with PAC.

Cationic PAM: Suitable for wastewater with high organic content or as a primary sludge dewatering agent.

Non-ionic PAM: Ideal for acidic or high-salinity wastewater.

Secco’s PAM Expertise: We provide a comprehensive portfolio of PAM (anionic, cationic, non-ionic) with tailored molecular weights and charge densities, ensuring the best fit for both clarification and dewatering stages.

3. Synergistic Application Process & Advantages

Typical Dosing Sequence:

PAC First: Added in a rapid mixing zone for charge neutralization and initial coagulation.

PAM Follows: Added in a slow mixing zone to promote floc growth and accelerate settling.

Synergistic Effects:

Increased Treatment Efficiency: The combination reduces settling time and can lower the footprint requirement for sedimentation tanks.

Reduces Chemical Costs: The use of PAM often allows for a 20-30% reduction in PAC dosage.

Improves Effluent Quality: Achieves >95% removal of Suspended Solids (SS) and reduces turbidity to below 10 NTU, meeting reuse or discharge standards.

Handles Complex Wastewater: Effectively treats the high SS, oil, and hardness characteristic of steel plant effluent.

Secco’s Integrated Approach: We offer technical support for optimized dosing protocols and product pairing, helping plants achieve maximum synergy and cost-effectiveness.

4. Key Considerations

Jar Testing is Essential: Bench-scale tests are necessary to determine the optimal types, dosages, and ratios of PAC and PAM (typical range: PAC 50-200 mg/L, PAM 0.5-5 mg/L).

pH Control: PAC performs best at pH 6.5-7.5; adjustment may be needed.

Proper Preparation & Dosing: PAM requires adequate dissolution (aging time ≥30 mins) to avoid “fish-eyes” and ensure full activity.

Sludge Management: The combined use may increase sludge volume, necessitating proper thickening and dewatering equipment.

5. Conclusion

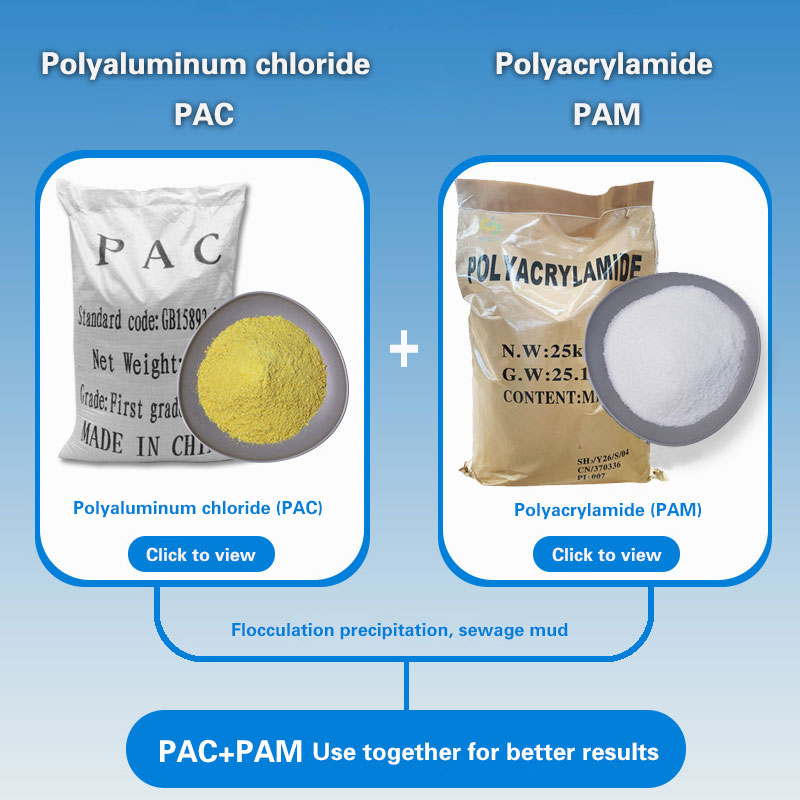

In steel plant wastewater treatment, PAC primarily provides “coagulation” for removing suspended and colloidal matter, while PAM enhances “flocculation” to speed up settling and improve sludge dewatering. Their synergy enables cost-effective and high-performance wastewater purification, making this combination a cornerstone for pretreatment and advanced treatment. Henan Secco Environmental Technology Co., Ltd. is committed to supplying reliable, high-performance PAM and PAC products, backed by technical expertise, to help steel plants achieve their water reuse and environmental compliance goals efficiently.