Circuit board is an important part of electronic components, but the waste water generated in the production process of circuit board contains a lot of pollutants, including copper, chromium, nickel, zinc, acid base and so on. If the circuit board waste water is not treated effectively, it will cause serious environmental pollution. When natural water is polluted by acids, alkalis and heavy metals, the water quality will deteriorate, the microbial activities will be inhibited or stopped, the self-purification capacity of water will be reduced, and the crops will be harmed. Heavy metal ions are not degraded by microorganisms. They can be absorbed and accumulated in living organisms, causing great harm to the human body and other organisms.

Therefore, it must be harmless treatment, in order to meet the corresponding emission standards. As a water treatment flocculant, polyacrylamide also plays an important role in circuit board wastewater.

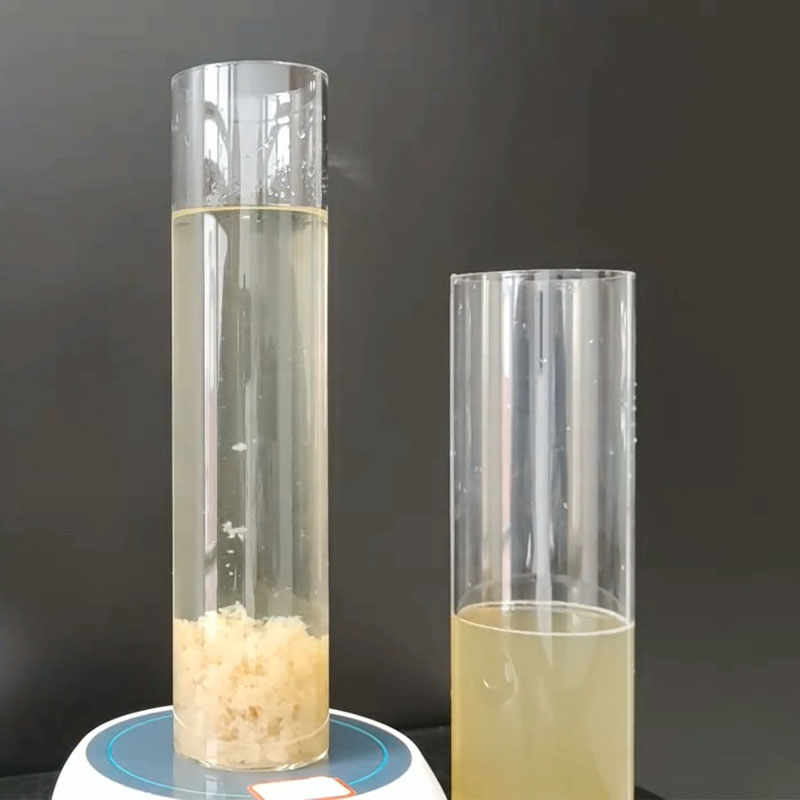

Circuit board complexing wastewater is mainly from acid/alkali etching production line and PTH production line. This type of wastewater typically has a pH of between 4 and 9. Wastewater not only contains complexing agents (the main complexing agent is ammonia < 50mg/L, formaldehyde, EDTA, etc.), and contains a large number of metal ions (such as Cu2+< 100mg/L). Complexing agent forms very stable complexes with heavy metal ions such as copper ions, because in the treatment of complexing agent wastewater, it needs to go through the regulating tank into the breaking reaction tower. In addition, breaking agent is added to make the complexed copper exist in the water in a free state. The collateralized wastewater enters the coagulation reaction tank. In the coagulation reaction pool to add polyacrylamide, polyaluminum chloride, polyferric sulfate and other water treatment agents, polyacrylamide in the coagulation reaction, mainly play a coagulation effect, the suspended ions in the wastewater produce electrical neutralization, eliminate the colloid surface charge in the wastewater repelling potential energy, so that colloid easy to condense and precipitate. After precipitation, the purified water enters the inclined tube sedimentation tank, the wastewater enters the pH recovery tank, and the sludge enters the sludge regulating tank. The sludge concentration is adjusted by adding cationic polyacrylamide. Due to the strong affinity of polyacrylamide for water, the colloidal particles in the suspended particles can be dehydrated, lose the digestion shell, and coagulate and precipitate. This can not only improve the removal efficiency of suspended solids, reduce the water content of sludge, reduce the amount of sludge, and thus increase the cleaning cycle of the sedimentation tank. After the regulation of the sludge pressure filtration, the sludge can be landfill or transported for disposal.