Have you ever wondered how murky river water transforms into the clear liquid that flows from your tap? Or how wastewater treatment plants remove invisible contaminants before releasing water back into the environment? The answer lies in two fundamental processes: coagulationand flocculation. Though often used interchangeably, these terms actually describe two distinct yet interconnected stages of water purification. Let’s delve into the fascinating science of how they work together to clean our water.

**Core Difference: Two Stages, One Mission**

Imagine trying to clean a pool full of glitter. Each tiny particle is too small and stubborn to settle on its own. This is the challenge water treatment plants face with microscopic pollutants. Here’s how they solve it:

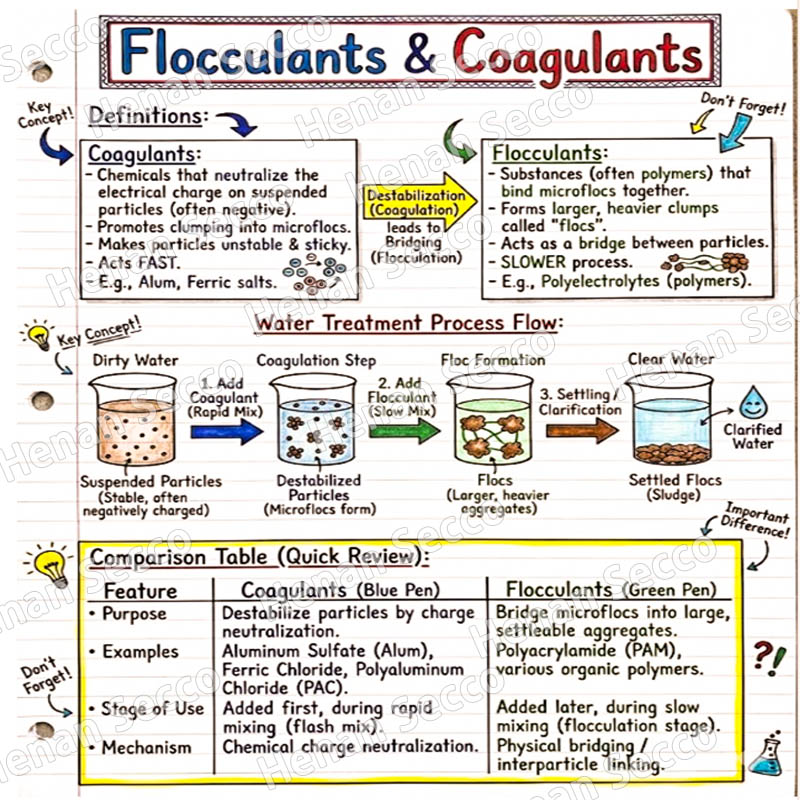

**Coagulation** is the destabilization stage. Tiny particles in water—such as clay, bacteria, and organic matter—usually carry a negative charge, which makes them repel each other and remain suspended. Coagulation works by adding positively charged chemicals (*coagulants*) to neutralize these negative charges. Think of it as introducing an “opposite magnet” that eliminates the repulsive force keeping particles apart. This stage requires rapid, intense mixing to ensure the coagulant contacts as many particles as possible within seconds.

**Flocculation** is the gathering stage. Once the particles are destabilized, they begin to form tiny clumps called *microflocs*. Flocculation gently encourages these microflocs to collide and bond into larger, visible aggregates known as *flocs* or *floccules*—like light, fluffy snowflakes in water. This phase involves slow, steady stirring over 15 to 45 minutes to promote particle collisions without breaking apart the delicate flocs.

**A Practical Analogy: Making a Snowball**

Think of coagulation and flocculation as steps in forming the perfect snowball:

– **Coagulation** is like adding just enough water to dry snow to make it “packable”—eliminating the repulsion between ice crystals.

– **Flocculation** is the gentle rolling and pressing of the snow in your hands to form a firm, growing snowball (the floc).

Without the right amount of water (coagulant), the snow remains loose and powdery. Without proper rolling (flocculation), you end up with a fragile, crumbly snowball.

**Common Chemicals: Key Agents in Water Treatment**

**Coagulants (Destabilizers)**

These are usually inorganic salts with a high positive charge:

– **Aluminum-based coagulants**

Alum (aluminum sulfate): The most widely used and traditional coagulant globally.

Polyaluminum chloride( PAC): More efficient across a broader pH range.

– **Iron-based coagulants**

Ferric chloride: Highly effective in phosphorus removal.

Ferric sulfate: Works well in cold water conditions.

Ferrous sulfate: Commonly used in wastewater treatment.

– **Organic polymers** (sometimes used as primary coagulants)

Cationic polymers: Positively charged chains that neutralize negative particles.

**Flocculants (Aggregators)**

These are typically long-chain organic polymers:

– ** Polyacrylamidederivatives** (the most common category)

Anionic PAM: Negatively charged, often used with metal coagulants.

Cationic PAM: Positively charged, offering dual functionality.

Non-ionic PAM: Electrically neutral, suitable for specific conditions.

– **Natural flocculants** (growing in popularity due to environmental sustainability)

Examples: chitosan, starch-based polymers.

**The Perfect Partnership: How They Work Together**

In a typical water treatment plant, these processes take place in sequence:

1. **Rapid Mix Tank**: Coagulant is injected into turbulent water (complete mixing within 1–30 seconds).

2. **Flocculation Tank**: Gentle paddle stirring for 20–45 minutes allows flocs to form and grow.

3. **Sedimentation Tank**: Large, heavy flocs settle out by gravity (now clearly visible to the eye).

4. **Filtration**: Remaining fine particles are captured in sand or membrane filters.

**Applications Beyond Tap Water**

– Wastewater treatment: Removing organic matter and nutrients before discharge.

– Mining operations: Separating minerals from process water.

– Food and beverage processing: Clarifying juices, wine, and syrups.

– Swimming pools: Maintaining clear, sparkling water.

– Industrial processes: Treating boiler feedwater and various process streams.

**Environmental Considerations**

Modern water treatment science aims to maximize efficiency while minimizing chemical usage and residual waste. Ongoing research explores:

– **Electrocoagulation**: Using electric current instead of chemicals.

– **Bioflocculants**: Microorganisms that naturally aggregate particles.

– **Smart dosing systems**: AI-controlled chemical feed based on real-time water quality.

**Conclusion**

Coagulation and flocculation represent one of humanity’s most vital public health innovations—a carefully choreographed “chemical dance” that makes modern sanitation possible. By understanding these processes, we gain insight into not only the science behind clean water but also the finely tuned engineering that sustains it.

With extensive experience and technical expertise in water treatment, **Henan Secco Environmental Technology Co., Ltd.** is dedicated to applying advanced coagulation and flocculation technologies across various water treatment scenarios. We provide efficient, eco-friendly, and tailored solutions to our clients, working together toward a cleaner water environment.