Proper dissolution of Polyacrylamide (PAM) is critical for achieving its optimal performance as a flocculant. Incorrect practices lead to clumping (“fish eyes”), gel formation, and molecular degradation, rendering it ineffective.

Before detailing the steps, understanding these fundamental principles is essential:

“Slow Sprinkle & Fast Stir” Rule: PAM powder must be sprinkled slowly and evenly into the stirred water. Never pour water into the powder, as this will cause instantaneous clumping that is nearly impossible to dissolve.

Controlled Agitation Speed: Stirring provides the shear force needed for dispersion and dissolution.

Initial Stage: Vigorous stirring (approx. 300-600 rpm) to create a vortex that pulls the powder down and disperses it instantly.

Later Stage: After dissolution, reduce to gentle stirring (approx. 40-60 rpm) to prevent shear degradation of the long polymer chains.

Use Neutral, Clean Water: Water quality and temperature are crucial.

Water Temperature: Room temperature tap water is ideal. Slightly warm water (40-50°C) can accelerate dissolution, but temperatures must never exceed 60°C as they will cause thermal degradation of the polymer.

Water Quality: Avoid using strongly acidic, alkaline, or high-salinity water unless specifically for treating such wastewater streams.

Preparation Concentration: Typically prepared as a 0.1% – 0.3% stock solution (i.e., 1-3 grams of PAM per liter of water). Higher concentrations will yield an overly viscous, gel-like solution that is hard to handle and dilute.

“Aging” Time: PAM requires time to fully hydrate and activate. The prepared solution should be left to “age” or “maturing” for 30-60 minutes after stirring to allow the polymer chains to fully extend, achieving maximum efficacy.

This is the most common and recommended method for lab-scale and small-to-medium batch preparation.

Equipment Needed:

Dissolution tank (Suitable materials: stainless steel, plastic, or fiberglass to avoid corrosion)

Mechanical stirrer (adjustable speed is highly recommended)

Weighing balance

Water supply

Step-by-Step Instructions:

Fill with Water: Fill the tank with the calculated volume of clean water (about 70-80% of the final desired volume).

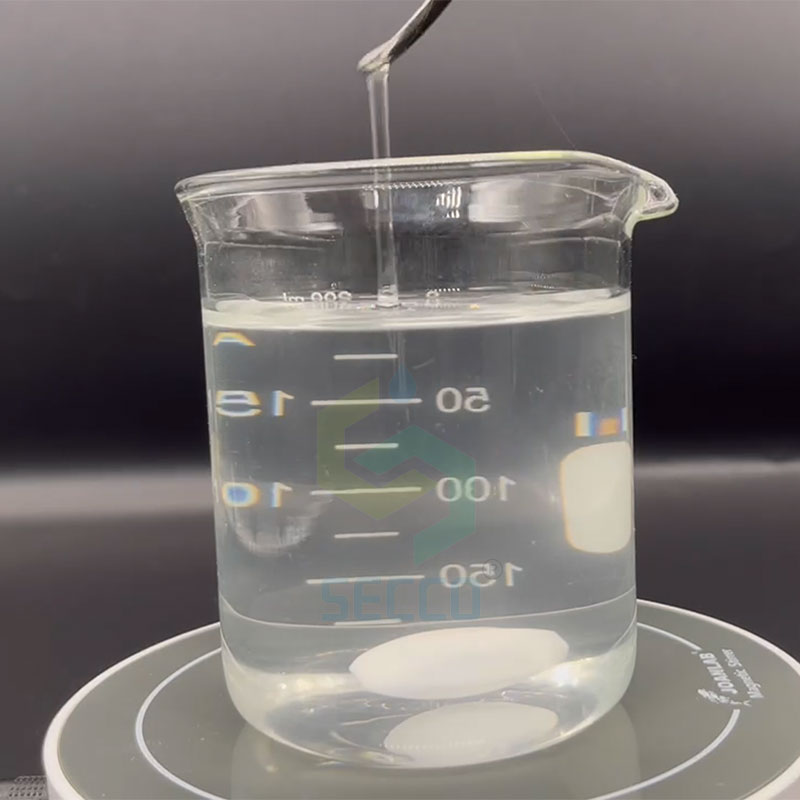

Initiate Stirring: Start the mixer at a medium-high speed (approx. 300-500 rpm) to create a strong, visible vortex in the water.

Sprinkle the Powder: Take the pre-weighed PAM powder and slowly and evenly sprinkle it onto the surface and into the vortex.

Critical: The powder should float and be drawn into the water individually, not in clumps.

Continue Stirring: After all powder is added, continue stirring for at least 30-60 minutes. Observe until the solution is uniform, clear, and free of any visible undissolved颗粒 (“fish eyes”).

Top Up and Slow Stir: Once fully dissolved, add the remaining water to reach the final volume. Reduce the stirring speed to low (approx. 40-60 rpm) for a few more minutes to ensure homogeneity without degrading the polymer.

Aging: Turn off the mixer and let the solution stand (age) for at least 30 minutes. The solution is now ready for use.

For large-scale industrial applications, automated systems are preferred.

Automatic Online Dilution / Preparation Unit

Principle: This integrated system combines water feeding, dry polymer dosing, wetting, mixing, and aging in one unit. A Venturi feeder or screw feeder draws and disperses PAM powder evenly into the water stream.

Advantages: High automation, consistent and efficient dissolution, eliminates human error and clumping. Ideal for continuous feeding in water/wastewater treatment plants.

Manual Mixing (For very small quantities or emergencies only)

Method: Add water to a container, then slowly sprinkle PAM while vigorously stirring with a rod or a low-speed electric mixer.

Disadvantages: Labor-intensive, high risk of clumping, and often results in incomplete dissolution. Not recommended for critical applications.

Anionic PAM: Generally the easiest and fastest to dissolve.

Non-ionic PAM: Dissolves slightly slower than anionic PAM.

Cationic PAM: Due to its positive charge and often higher molecular weight, it typically dissolves the slowest and is most sensitive to shear degradation. Use lower stirring speeds and longer aging times for cationic PAM.

| Problem | Possible Cause | Solution |

|---|---|---|

| Clumping (“Fish Eyes”) | 1. Powder added too quickly 2. Powder dumped into still water 3. Insufficient agitation |

1. Stop adding powder, increase stir speed to try to break lumps. 2. If severe, discard the batch. Always ensure “Slow Sprinkle & Fast Stir.” |

| Low Viscosity / Poor Performance | 1. Insufficient dissolution/aging time 2. Excessive shear degradation from stirring 3. Water temperature too high 4. Product degradation or quality issue |

1. Ensure sufficient stirring and aging time. 2. Reduce agitation speed after initial dissolution. 3. Use room temperature or lukewarm water (<50°C). 4. Check product shelf life and storage conditions. |

| Solution Stratifies (Layers) | Normal phenomenon, especially after prolonged standing. | Gently stir before use. It is recommended to prepare fresh solutions and use within 24 hours. |

Best Practice Mantra:

Vortex in water, sprinkle powder slow,

Stir fast then gentle, let the polymer grow.

Room temp is best, avoid the heat,

Aging brings the performance neat.