Fish cannery wastewater is a typical high-concentration, high-turbidity, and poorly biodegradable organic effluent from food processing. Traditional physical sedimentation methods are inefficient, while direct biological treatment is overloaded. As a high-performance polymeric flocculant, polyacrylamide plays the central role of a “scavenger” and “accelerator” in this process.

I. Core Mechanisms of Action

PAM utilizes its ultra-long molecular chains and specific functional groups to perform three primary functions:

Charge Neutralization:

Problem: Numerous colloidal particles in the wastewater, such as proteins and amino acids, carry negative surface charges. They repel each other, forming a stable suspended system that resists settling.

PAM’s Solution: The positive charge groups of Cationic PAM effectively neutralize the negative charges on these colloidal particles, destabilizing them and allowing particles to aggregate.

Adsorption and Bridging (The Most Critical Mechanism):

PAM molecular chains act like countless “tiny ropes.” Their active sites can simultaneously adsorb multiple destabilized suspended particles, colloids, and dissolved organic matter.

Through this “bridging” connection, microscopic, hard-to-settle particles in the water are aggregated and bound together, forming large, dense, and visible “flocs.” During this process, fats, oils, and fine fish meat fibers are also entrapped and enmeshed.

Sweep Flocculation:

As the large flocs settle, they function like a descending “filtration net,” capturing and sweeping finer suspended particles along their path, achieving in-depth purification.

II. Treatment Efficacy and Advantages

The addition of suitable PAM to fish cannery wastewater delivers the following immediate and visible results:

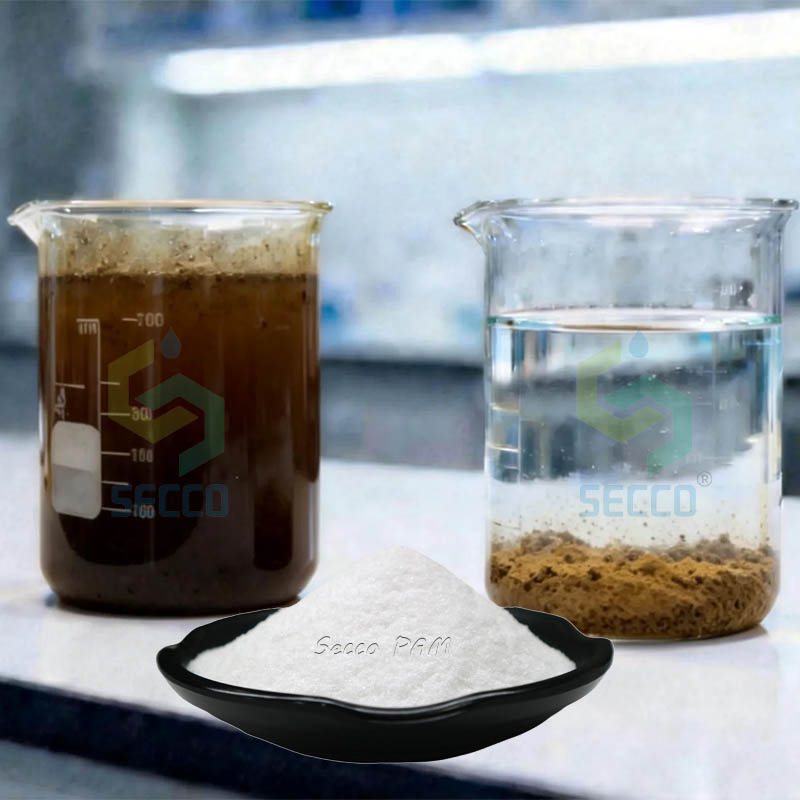

Highly Efficient Solid-Liquid Separation, Dramatically Reduces Turbidity and SS:

Result: Turbid wastewater separates into distinct layers within minutes, producing a clear supernatant.

Data: Suspended Solids removal rates typically exceed 90%, and turbidity reduction often reaches 95% or higher. This is the most直观 and significant effect.

Effective Removal of Fats, Oils, and Colloidal Organics:

Result: Flocculation entraps emulsified oils, dissolved proteins, and colloidal substances into the settling flocs.

Advantage: Significantly reduces the wastewater’s COD and BOD, alleviating the load on subsequent biological treatment units (e.g., UASB, aerobic tanks) and enhancing the stability and efficiency of the entire treatment system. Primary COD removal typically ranges from 30% to 60%.

Improves Sludge Devaterability:

Result: The settled sludge (primarily organic) is denser and has a relatively lower water content.

Advantage: In the subsequent sludge dewatering stage (using filter presses, centrifuges), another dose of PAM (usually cationic) can further squeeze water from the sludge, forming firm filter cakes and significantly reducing sludge volume (by up to 70% or more), drastically cutting sludge hauling and disposal costs.

High Comprehensive Economic Benefit:

Low Dosage, High Efficiency: As a coagulant aid, PAM is highly effective at very low dosages (ppm levels).

Reduces Overall Operating Costs: By enhancing pre-treatment efficiency, it protects downstream biological units, reduces the risk of equipment clogging, and lowers power and overall chemical consumption, offering excellent cost-effectiveness.

III. Key Points for Product Selection and Application

Given the complexity of fish cannery wastewater, correct product selection and application are crucial:

Product Selection Recommendation:

First Choice: Cationic Polyacrylamide (CPAM). Due to the high content of negatively charged colloidal organics (proteins, fatty acids, etc.), CPAM’s dual action of charge neutralization and adsorption bridging is most effective.

Alternative/Coagulant Combination: For some water qualities or pre-treatment stages, Anionic Polyacrylamide can be used in combination with inorganic coagulants (e.g., PAC, Polyaluminum Chloride). PAC is added first for charge neutralization and initial coagulation, followed by APAM for bridging and large floc formation.

Molecular Weight: Typically, medium-high to high molecular weight products are selected to ensure strong bridging capability and the formation of large, robust flocs.

Application Process:

text

Raw Wastewater → Screen (removes large solids) → Equalization Tank (homogenizes flow/load) → **【Core Treatment Unit】** → Sedimentation Tank/DAF Unit → To Biological System

↓

**Flocculation Reaction Tank**

↓

**1. Rapid Mix: Add PAC (Optional)**

↓

**2. Slow Mix: Add PAM Solution**

Important Notes:

Dissolution: Must be prepared using proper dissolution equipment to ensure complete hydration into a uniform colloidal solution, avoiding “fish eyes” that impair performance.

Dosing Point & Mixing: The dosing point should be in a zone with gentle mixing. Vigorous agitation can shear and break apart formed flocs.

Jar Testing is Critical: It is strongly recommended to conduct jar tests with the specific customer’s wastewater to determine the optimal PAM type, dosage, and sequence. Water characteristics vary between factories and even seasons.

Conclusion

For fish canneries, polyacrylamide is not an optional additive but a key chemical essential for achieving effluent compliance and reducing treatment costs. It rapidly transforms difficult-to-treat, “soupy” wastewater into “clear water” and “manageable sludge,” effectively unblocking the “bottleneck” of the entire treatment process.

As a manufacturer, offering free jar testing services and providing customized chemical selection and dosing proposals based on visual demonstration of results will be the most persuasive form of sales and technical support.

If you have any more questions about the wastewater treatment using polyacrylamide, please feel free to contact Henan Secco at any time!